Engineering

With unsurpassed customer support, WRWP Engineering is a virtual extension of your technical team:

- Seamlessly integrating into and adapting to your processes and CADD/CAE protocols and flexing to meet or exceed your technical needs.

- Maximizing your product’s potential by objectively evaluating and applying industry standards, recommended practices, proven trends and advances in technologies.

- Continually adding VALUE by optimizing your product’s functional worthiness v. its total cost.

- Discovering, designing & developing electrical/electronic systems and devices to enhance your product with Design-for-Producibility (DfP) and installation-ability.

- Countering potential risks and partnering with you to verify and validate your product.

Single Point of Contact

Whether built domestically or at one of our offshore locations, all customer service, engineering, quality assurance, and invoicing will be handled easily right here in the USA. This helps us to be flexible and responsive to our customer needs and maintain the best customer service in our industry.

Cost Effective Offshore Tooling

Component lead times and pricing sometimes make it more cost effective to tool up substitute parts. Our engineers work with our offshore facilities to design, make improvements, and test substitutes. We also work with our customers on special projects to help develop a new component that isn’t available commercially off the shelf.

Molding

We can tool and injection mold custom grommets, strain reliefs, and connection systems to meet your needs.

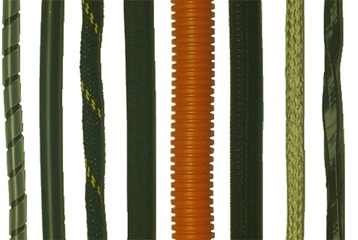

Harness Covering

WRWP works with many different harness coverings including tape wrap, convoluted tubing, braided nylon, and braided steel tubular sleeving.

Sonic Welding / Splice

Our splice and ultrasonic welding capabilities allow us to streamline harness configurations for lowest cost processing.

Quality Assurance

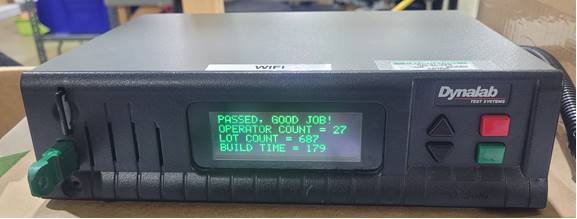

Most of our locations are certified to ISO 9001:2015 with our quality and build personnel certified to IPC/WHMA-A-620 standards, ensuring top-notch quality at every production stage. Whether you need us to produce parts to UL requirements or complete comprehensive quality inspections with our advanced Dynalab circuit analyzers on assemblies, we ensure every detail meets your specifications.

But that's not all—our team is proficient in fulfilling all your AIAG APQP and PPAP quality standard needs. We comply with a range of environmental standards including REACH, RoHS, POP, TSCA, PFAS and Prop65, and are capable of providing certificates of conformance and traceability for all production lots and shipments.

With WRWP, you're choosing unparalleled quality, meticulous compliance, and environmental responsibility. Trust us to deliver excellence every time.

WRWP also uses Cirris testers with electrical circuit analyzed assembly boards to build and test simultaneously during the assembly process.